自動(dòng)焊接專機(jī)與焊接機(jī)器人的比較分析

來源:http://m.hongqicables.com/ 發(fā)布時(shí)間:2023-06-13 瀏覽次數(shù):0

自動(dòng)焊(自動(dòng)化焊接)是指將自動(dòng)化、智能化的控制系統(tǒng)和焊接工藝有機(jī)結(jié)合。自動(dòng)化焊接設(shè)備主要是常用設(shè)備包括自動(dòng)焊接專機(jī)和焊接機(jī)器人等,這些自動(dòng)焊接設(shè)備的使用,提高了生產(chǎn)效率、提升了制造質(zhì)量、減輕了人工的工作量和工作程度;實(shí)現(xiàn)二十四小時(shí)的連續(xù)工作,很大程度地代替了人工勞動(dòng)力。

Automatic welding refers to the organic combination of automated and intelligent control systems and welding processes. Automatic welding equipment is mainly commonly used equipment, including automatic welding machines and welding robots. The use of these automatic welding equipment improves production efficiency, improves manufacturing quality, and reduces the workload and degree of labor; Achieving 24-hour continuous work has largely replaced manual labor.

下面山東焊接專機(jī)廠家來講講自動(dòng)焊接專機(jī)與焊接機(jī)器人的比較:

Below, Shandong welding machine manufacturers will talk about the comparison between automatic welding machines and welding robots:

自動(dòng)化焊接專機(jī)的結(jié)構(gòu)及應(yīng)用

Structure and Application of Automatic Welding Machine

自動(dòng)化焊接專機(jī)主要由焊接系統(tǒng)、機(jī)械系統(tǒng)和電氣控制系統(tǒng)組成。需要人工或機(jī)械手來上下料,通過焊接夾具完成工件的固定和定位,并自動(dòng)啟動(dòng)電源的電弧,自動(dòng)送絲機(jī)、自動(dòng)移動(dòng)、自動(dòng)退回,人工或機(jī)械手在取下工件。

The automatic welding machine mainly consists of a welding system, mechanical system, and electrical control system. It requires manual or mechanical hands to load and unload materials, complete the fixation and positioning of the workpiece through welding fixtures, and automatically start the arc of the power supply, automatic wire feeding machine, automatic movement, and automatic return. Manual or mechanical hands are used to remove the workpiece.

焊接系統(tǒng)包括焊接電源和焊槍,機(jī)械手系統(tǒng)主要由床身機(jī)構(gòu)、工裝夾具、工裝輔助支撐機(jī)構(gòu)、焊槍微調(diào)機(jī)構(gòu)、焊接工件和焊槍移動(dòng)機(jī)構(gòu)組成。電氣系統(tǒng)主要控制夾具的裝夾和定位,焊機(jī)的啟動(dòng)和停止,焊槍或工件的運(yùn)動(dòng),輸送裝置等。

The welding system includes Welding power supply and welding gun. The manipulator system is mainly composed of machine body mechanism, tooling fixture, tooling auxiliary support mechanism, welding gun trimming mechanism, welding workpiece and welding gun moving mechanism. The electrical system mainly controls the clamping and positioning of fixtures, the start and stop of welding machines, the movement of welding guns or workpieces, and conveying devices.

自動(dòng)化焊接專機(jī)主要采用雙絲焊接,如在推土機(jī)的生產(chǎn)中,可以應(yīng)用于主臂焊接、車架的主焊接等。焊接專機(jī)的使用大大提高了生產(chǎn)效率,一般為人工單絲焊接2倍,此處同人工焊接相比,焊接專機(jī)的焊縫沒有斷弧,且雙絲焊接的熔深較深,因此提高了焊縫的力學(xué)性能。

Automatic welding machines mainly use double wire welding, such as in the production of bulldozers, which can be applied to the welding of the main arm and the main welding of the frame. The use of welding machines greatly improves production efficiency, usually twice that of manual single wire welding. Compared with manual welding, the welding seam of the welding machine does not have arc breaks, and the penetration depth of double wire welding is deeper, thus improving the mechanical properties of the weld seam.

自動(dòng)化焊接專機(jī)自適應(yīng)控制類專機(jī),是一種自動(dòng)化程度較高的焊接設(shè)備,通過配備的傳感器和電子檢測(cè)路線,對(duì)焊縫的軌跡自動(dòng)跟蹤導(dǎo)向,有的甚可以完成核對(duì)的設(shè)備和調(diào)試。此外還有智能化的焊接專機(jī),能夠利用高等級(jí)的傳感器。

Automatic welding machine adaptive control type special machine is a highly automated welding equipment, which is equipped with sensors and electronic detection routes to automatically track and guide the trajectory of the weld seam. Some can even complete equipment verification and debugging. In addition, there is an intelligent welding machine that can utilize high-level sensors.

焊接機(jī)器人的結(jié)構(gòu)及應(yīng)用

Structure and Application of Welding Robot

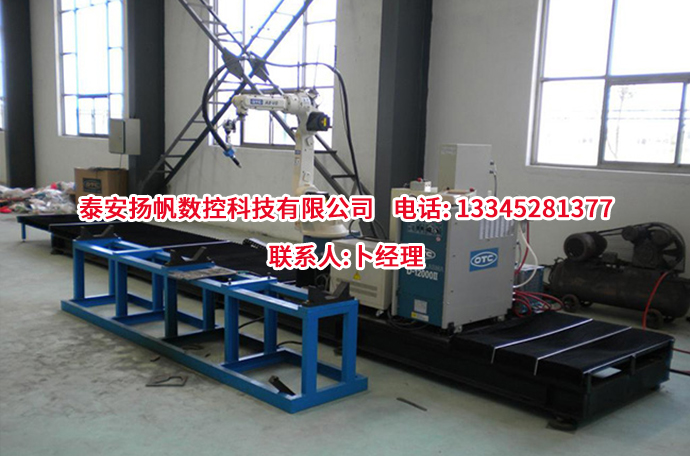

焊接機(jī)器人結(jié)構(gòu)主要有機(jī)器人本體和控制器、焊接電源、機(jī)器人外軸行走機(jī)構(gòu)、焊接變位機(jī)和夾具、操作軟件和弧焊軟件包、傳感系統(tǒng)、工作站輔助及除塵系統(tǒng)等。

The structure of welding robot mainly includes robot body and controller, Welding power supply, robot external axis travel mechanism, welding positioner and fixture, operation software and arc welding software package, sensor system, workstation auxiliary and dust removal system, etc.

焊接機(jī)器人具有柔性化和數(shù)字化程度高、焊接質(zhì)量穩(wěn)定、焊接精度高等特點(diǎn),在改善焊接產(chǎn)品質(zhì)量、提高機(jī)械制造企業(yè)生產(chǎn)能力和競(jìng)爭(zhēng)能力方面起到了重要作用。

Welding robots have the characteristics of high flexibility and digitization, stable welding quality, and high welding accuracy, playing an important role in improving the quality of welding products, enhancing the production capacity and competitiveness of mechanical manufacturing enterprises.

從傳統(tǒng)的焊接操作機(jī)、座式變位機(jī)、滾輪架和翻轉(zhuǎn)機(jī)等,到如今系統(tǒng)化、智能化的焊接專機(jī)、焊接生產(chǎn)線和機(jī)器人設(shè)備。就焊接操作機(jī)而言,從傳統(tǒng)的立柱橫梁式操作機(jī),到現(xiàn)在多種結(jié)構(gòu)形式的龍門式、門框式、臺(tái)式、側(cè)梁式等,可以發(fā)現(xiàn),焊接操作機(jī)的種類越來越多,規(guī)格越來越大型化。您有需求就來咨詢聯(lián)系我們http://m.hongqicables.com吧!

From traditional welding operators, seat displacement machines, roller racks, and flippers, to today's systematic and intelligent welding machines, welding production lines, and robot equipment. As for welding operators, from the traditional column and beam type operators to various structural forms such as gantry, door frame, desktop, and side beam types, it can be observed that there are more and more types of welding operators and their specifications are becoming larger and larger. If you have any needs, please contact us for consultation http://m.hongqicables.com Come on!

上一篇:技術(shù)人員使用數(shù)控焊接設(shè)備如何保障?

下一篇:數(shù)控焊接設(shè)備工藝的一些要點(diǎn)總結(jié)