焊接機器人、焊接機械手和焊接專機之間的差異

來源:http://m.hongqicables.com/ 發(fā)布時間:2023-05-09 瀏覽次數(shù):0

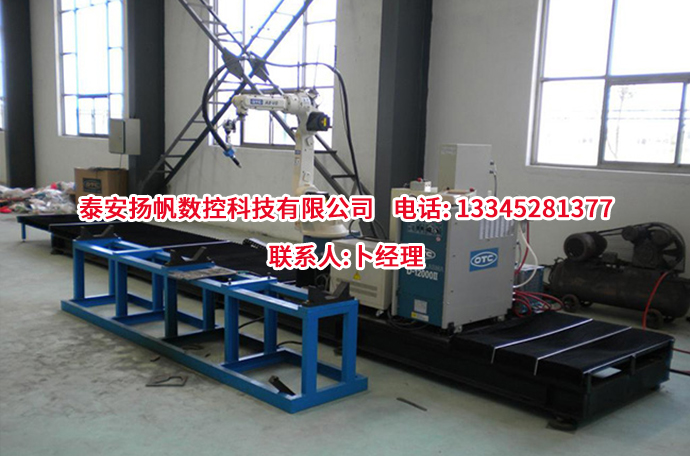

焊接行業(yè)為了順應(yīng)社會經(jīng)濟發(fā)展的步伐,開始進行轉(zhuǎn)型升級,使用自動焊接設(shè)備完成焊接工作,焊接機器人廠家隨之發(fā)展起來,出現(xiàn)了焊接機器人,焊接機械手和山東焊接專機等自動焊接設(shè)備,小編帶您了解它們之間都有什么差異。

In order to adapt to the pace of social and economic development, the welding industry has begun to undergo transformation and upgrading, using automatic welding equipment to complete welding work. Welding robot manufacturers have also developed, and automatic welding equipment such as welding robots, welding robots, and Shandong welding specialized machines have emerged. I will take you to understand the differences between them.

在焊接市場中,焊接機器人和焊接機械手都是機器人,只是叫法不同,在很多廠家中就會出現(xiàn)焊接機器人和焊接機械手,企業(yè)在選擇的時候不需要對比兩者,這只是同一種產(chǎn)品的不用叫法。

In the welding market, welding robots and welding robots are both robots, but their names are different. In many manufacturers, welding robots and welding robots appear. Enterprises do not need to compare the two when choosing, this is just a different name for the same product.

1、在中,焊接專機比焊接機器人更有競爭優(yōu)勢,市場上的焊接機器人配備多種焊接功能,所以相對于較高一些,焊接專機較低。

1. In terms of price, welding machines have a competitive advantage over welding robots. Welding robots in the market are equipped with multiple welding functions, so compared to higher prices, welding machines have lower prices.

2、兩者結(jié)構(gòu)不同,焊接專機主要是由焊接系統(tǒng)、機械系統(tǒng)和電氣系統(tǒng)組成,焊接機器人主要包括機器人本體和控制器、焊接電源、機器人行走機構(gòu)、焊接變位機及夾具、傳感系統(tǒng)、保護系統(tǒng)等,焊接機器人的結(jié)構(gòu)比焊接專機更加緊湊,自動化水平較高。

2. The two have different structures. The welding machine is mainly composed of a welding system, mechanical system, and electrical system. The welding robot mainly includes the robot body and controller, welding power supply, robot walking mechanism, welding displacement machine and fixture, sensing system, protection system, etc. The structure of the welding robot is more compact than that of the welding machine, with a higher level of automation.

3、兩者應(yīng)用范圍不同,焊接專機是專門針對某類特殊的產(chǎn)品來進行自動焊接,通常只用來焊接環(huán)形或者直焊縫,而焊接機器人采用伺服控制系統(tǒng),具備3-6個自由度,可以焊接不同方位的焊縫,針對較復(fù)雜的工件也能輕松焊接。

3. The application scope of the two is different. The welding machine is specifically designed for automatic welding of a specific type of product, usually only used for welding circular or straight welds. The welding robot adopts a servo control system, which has 3-6 degrees of freedom and can weld welds in different directions. It can also easily weld more complex workpieces.

4、兩者焊接范圍,不同焊接機器人除去基礎(chǔ)的配備外,還可以加裝多個輔助設(shè)備,延長焊接范圍,針對大型或者較長的工件也能進行焊接,大大提高了焊接范圍。

4. In addition to basic equipment, different welding robots can also install multiple auxiliary equipment to extend the welding range, and can also weld large or long workpieces, greatly improving the welding range.

以上就是焊接機器人、焊接機械手和焊接專機的區(qū)別。企業(yè)可以通過工件的實際操作來選用合適的自動焊接設(shè)備,三者都可以幫助企業(yè)提高焊接效率,穩(wěn)定產(chǎn)品質(zhì)量。更多相關(guān)內(nèi)容就來我們網(wǎng)站http://m.hongqicables.com咨詢了解吧!

The above is the difference between welding robots, welding robots, and welding specialized machines. Enterprises can choose appropriate automatic welding equipment through the actual operation of workpieces, and all three can help improve welding efficiency and stabilize product quality. For more related content, come to our website http://m.hongqicables.com Consult and understand!